RENATUS NETWORK

Concept

Token Lending

by lending out purchased tokens to logistics companies, token owners can earn recurring revenue.

1 token

= 1 storage container

the small size of the securities enables high liquidity, and token transactions can be made worldwide.

Scaling warehouse size

to the number of tokens issued

The more tokens sold, the larger the warehouse constructed.

RENATUS NETWORK

Concept

Token Lending

by lending out purchased tokens to logistics companies, token owners can earn recurring revenue.

1 storage container = 1 token

the small size of the securities enables high liquidity, and token transactions can be made worldwide.

Scaling warehouse size to the number of tokens issued

The more tokens sold, the larger the warehouse constructed.

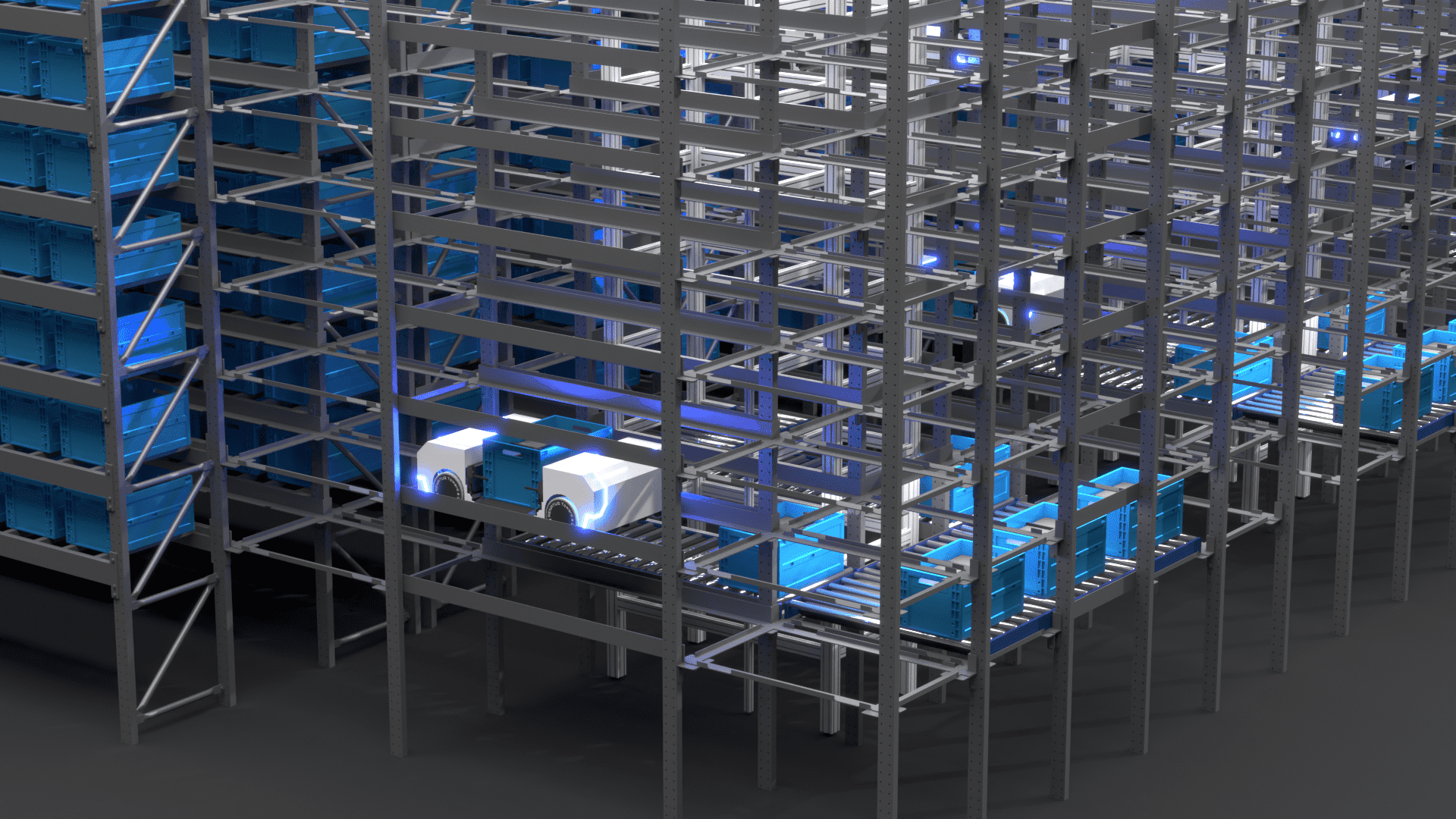

Product

The world’s largest automated storage

and retrieval system.

RENATUS NETWORK is not just a single facility,

but a transcontinental network of warehouses.

You can be storing and sending your goods from one coast to the other

without any interruptions in your operations.

Our optimizing system will predict future demand and automatically allocate

and move your goods to the optimal sites in the network.

RENATUSCORTEX

detail

Advanced algorithms enable comprehensive fleet control of robots. RENATUS is one of the first products in the world to implement practical algorithms that enable high-speed robot travel while optimizing for efficiency in both travel distance and material flow.

detail

RENATUS CORTEX constantly monitors the status of all equipment. If some robot, lift, or other equipment fails, it instantly calculates a new route that bypasses the failed part(s), allowing the system to continue operation without stopping the entire system as in traditional systems.

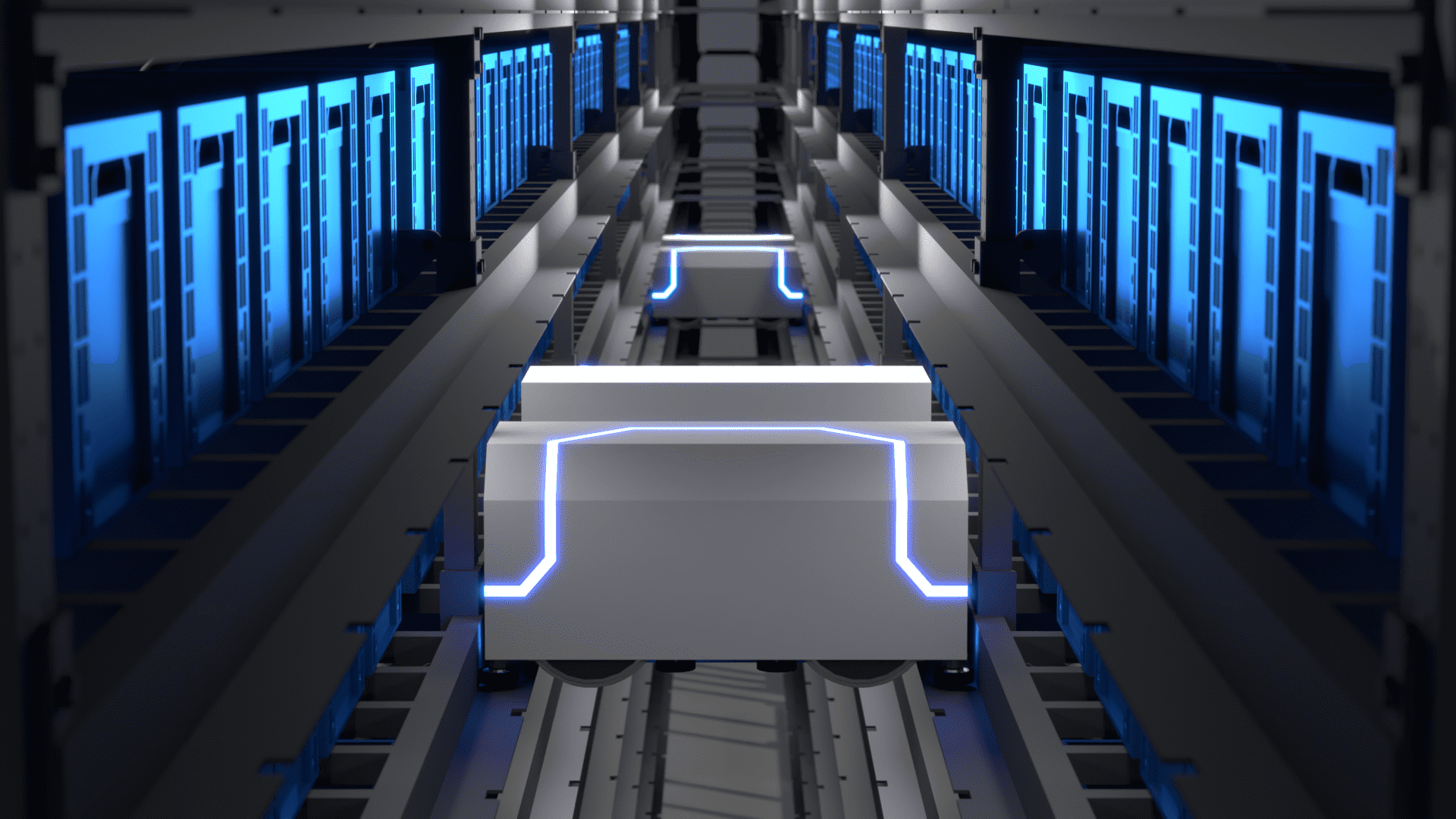

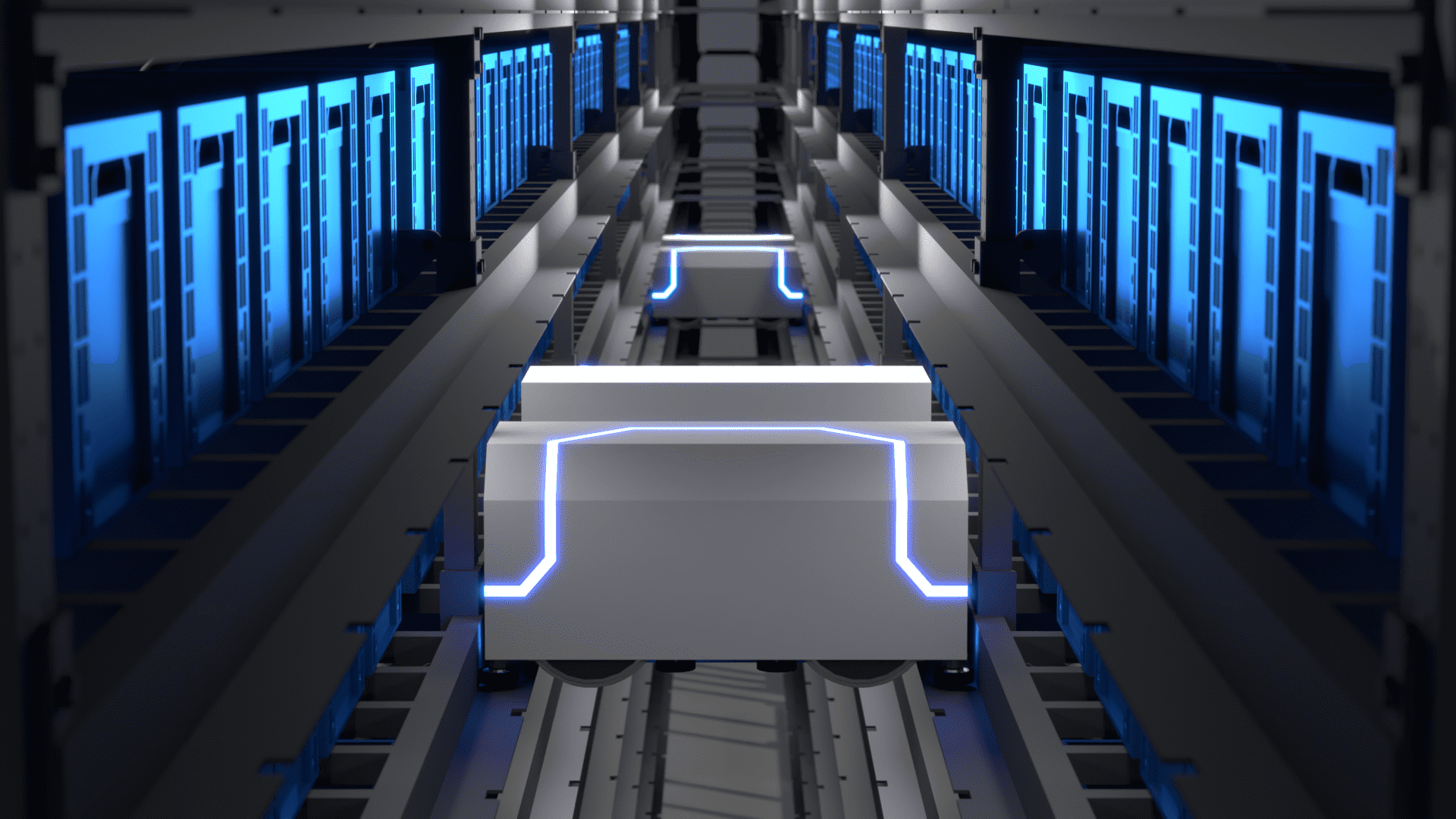

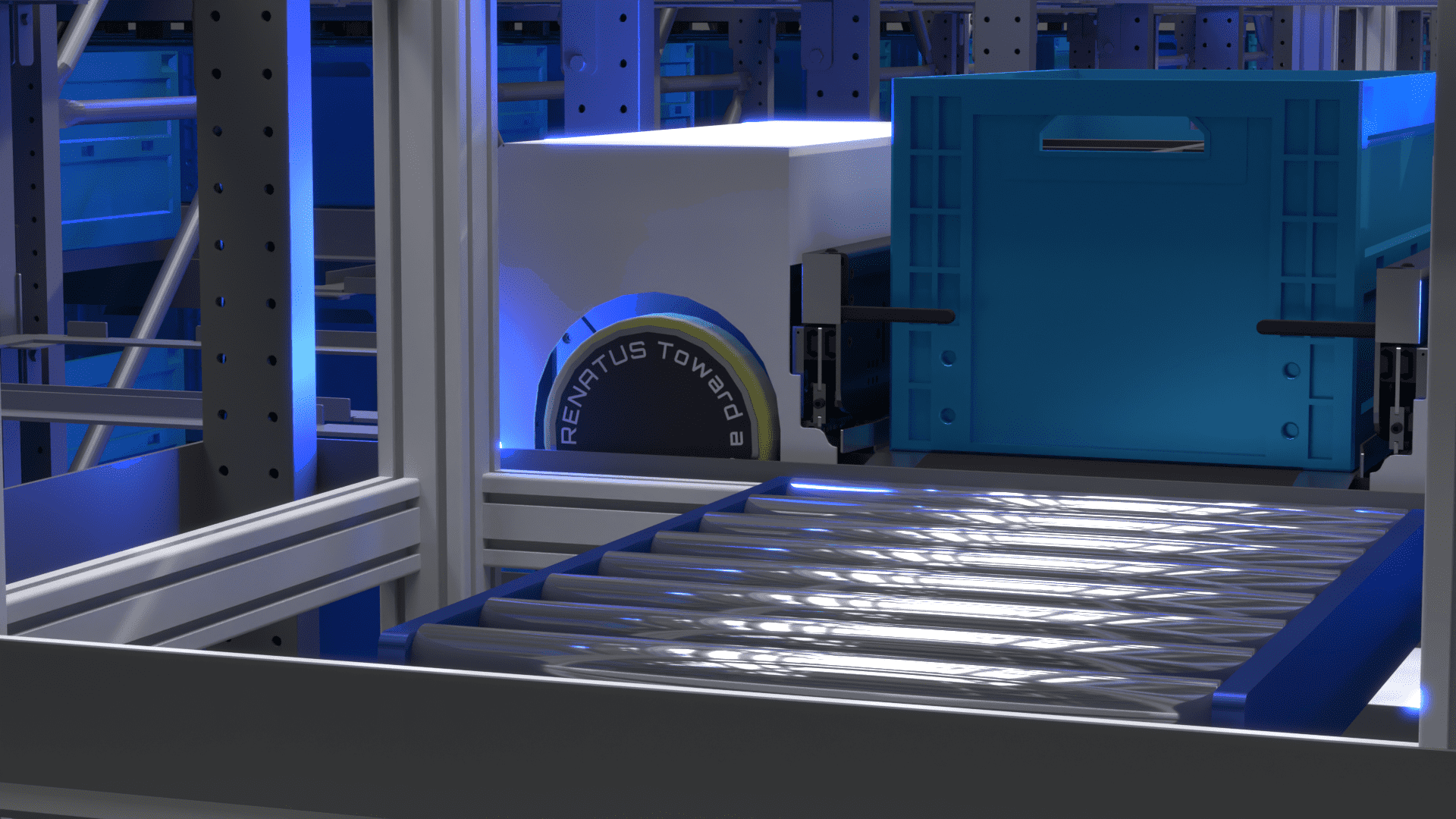

RENATUS SHUTTLE

the robot is one of the fastest in the industry while maintaining precision down to the millimeter.

detail

The robot is equipped with high-power motors and can move at a speed of 4 m/s. By quickly changing direction along the vertical and horizontal rails of the RENATUS storage racks, SHUTTLE transports goods along the shortest route at the fastest speed.

detail

The high-speed transfer module can load and unload storage containers in 5 seconds. Advanced sensors built into the robot monitor the container status to ensure a safe yet fast transfer of goods.

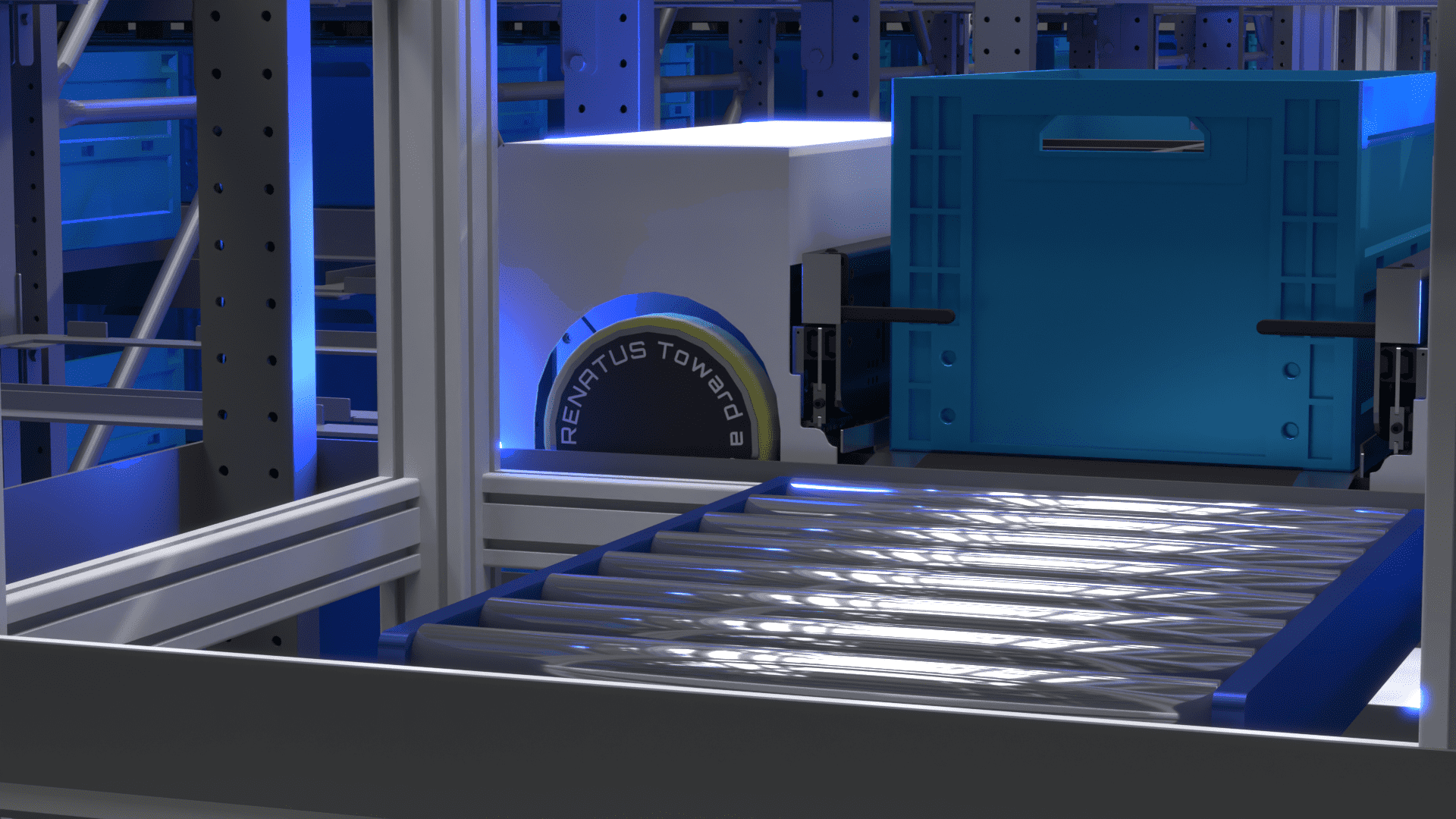

RENATUS STATION

detail

Workers have immediate access to a continuous supply of pre-sequenced containers to pick items from as well as the appropriate shipping cartons needed to pack and ship the order. This enables one-stop, continuous operation of (1) item picking, (2) consolidation, and (3) packing.

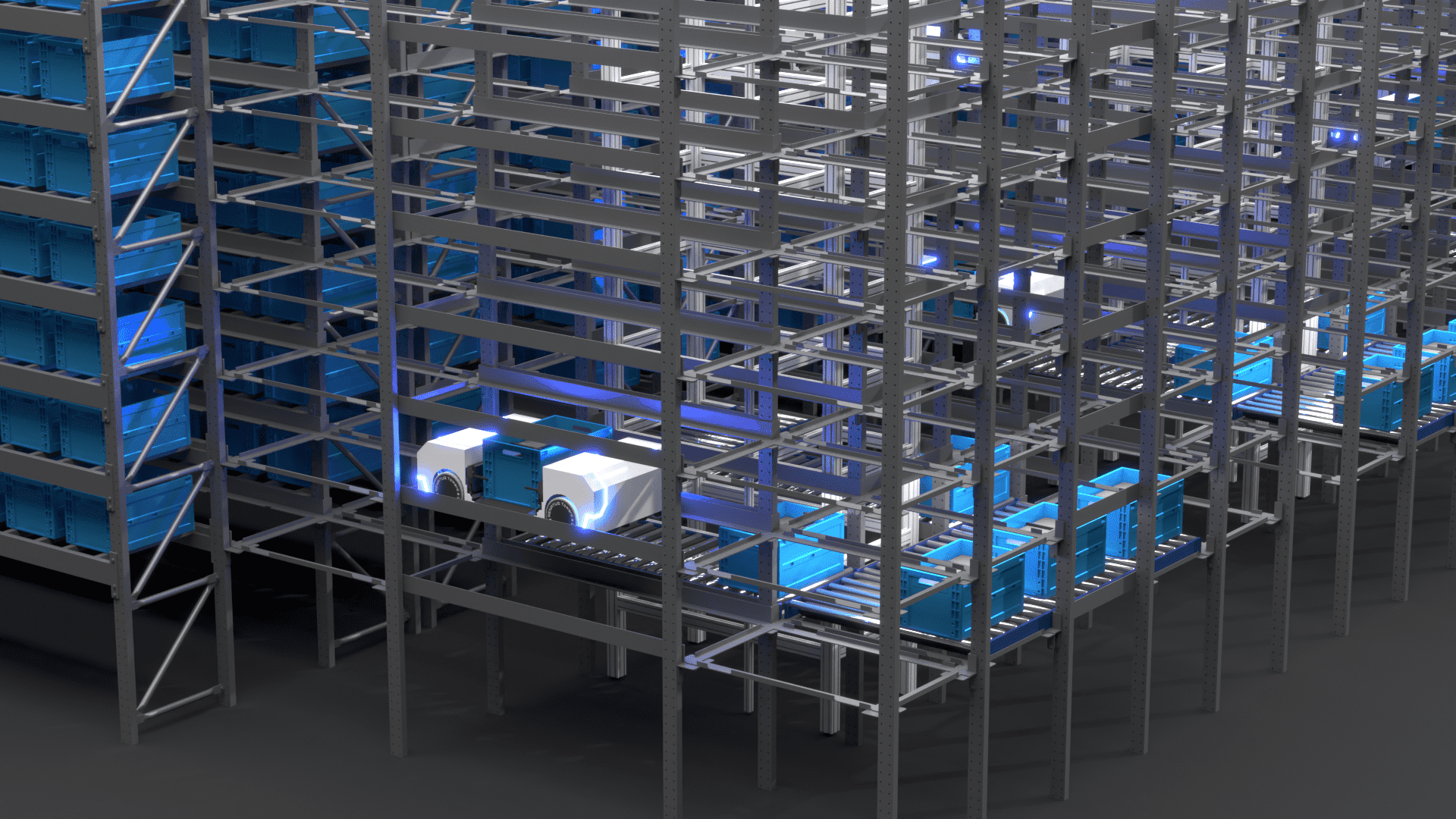

RENATUS RACK

detail

Partitions can be built into the containers to further reduce the area. Customization is also possible according to the customer’s warehouse volume and shape.

detail

The proprietary high-speed lift reaches one of the fastest speeds in the industry of 4 m/s. Containers are delivered to RENATUS STATION almost instantaneously regardless of what level in the racks they are stored.

PV

Product

The world’s largest

automated storage

and retrieval system.

RENATUS NETWORK is not just a single facility, but a transcontinental network of warehouses. You can be storing and sending your goods from one coast to the other without any interruptions in your operations.

Our optimizing system will predict future demand and automatically allocate and move your goods to the optimal sites in the network.

RENATUSCORTEX

detail

Advanced algorithms enable fleet control of up to 2000 robots, one of the highest capabilities in the industry. RENATUS is one of the first products in the world to implement practical algorithms that enable high-speed robot travel while optimizing for efficiency in both travel distance and material flow.

detail

RENATUS CORTEX constantly monitors the status of all equipment. If some robot, lift, or other equipment fails, it instantly calculates a new route that bypasses the failed part(s), allowing the system to continue operation without stopping the entire system as in traditional systems.

RENATUS SHUTTLE

detail

The robot is equipped with high-power motors and can move at a speed of 4 m/s. By quickly changing direction along the vertical and horizontal rails of the RENATUS storage racks, SHUTTLE transports goods along the shortest route at the fastest speed.

detail

The high-speed transfer module can load and unload storage containers in 5 seconds. Advanced sensors built into the robot monitor the container status to ensure a safe yet fast transfer of goods.

RENATUS STATION

detail

Workers have immediate access to a continuous supply of pre-sequenced containers to pick items from as well as the appropriate shipping cartons needed to pack and ship the order. This enables one-stop, continuous operation of (1) item picking, (2) consolidation, and (3) packing.

detail

The introduction of high-speed picking robots can fully automate and speed up the process of item picking. A proprietary algorithm enables the high-speed transfer of even more complex items.

RENATUS RACK

detail

The unique rack design enables high-density storage of 29 containers per square meter (or 3 containers per square foot). Each container can be partitioned to fit multiple kinds of items. Layouts are highly customizable according to customer needs and requirements.

detail

The proprietary high-speed lift reaches one of the fastest speeds in the industry of 4 m/s. Containers are delivered to RENATUS STATION almost instantaneously regardless of what level in the racks they are stored.

PV

Token

$CNTN

Container Token

$CNTN

Container Token

Token which compartmentalizes ownership of RENATUS automated warehouse as 1 $CNTN = 1 storage container. Earn recurring revenue by lending out owned tokens to e-Commerce or logistics companies.

Business Model

Business Model

Economics

Warehouse income/expense simulation

for a single year

A warehouse property is considered a single real estate income unit and is modeled as such.

cumulative profits

Payback period of about 3 years (ROI: 28-42%) by operating an efficient automated system.

Roadmap

Incentive Plan

Token Sales Schedule

1. AL Distribution

2. Private Sale

3. Public Sale

Reward for early buyers

| $CNTN Cumulative total sales | Airdrop recipients (early buyers) | $CNTN Number of airdrops |

| 333 CNTN | 100 CNTN | 10 CNTN |

| 1,000 | 333 | 33 |

| 3,333 | 1,000 | 100 |

| 10,000 | 3,333 | 333 |

| 33,333 | 10,000 | 1,000 |

| 100,000 | 33,333 | 3,333 |

*Airdropped tokens are prorated according to the percentage of ownership.

*Fractional amounts are rounded down.

Roadmap

Incentive Plan

Token Sales Schedule

1. AL Distribution

2. Private Sale

3. Public Sale

APY

25-42%

Reward for early buyers

| $CNTN Cumulative total sales | Airdrop recipients (early buyers) | $CNTN Number of airdrops |

| 333 CNTN | 100 CNTN | 10 CNTN |

| 1,000 | 333 | 33 |

| 3,333 | 1,000 | 100 |

| 10,000 | 3,333 | 333 |

| 33,333 | 10,000 | 1,000 |

| 100,000 | 33,333 | 3,333 |

*Airdropped tokens are prorated according to the percentage of ownership.

*Fractional amounts are rounded down.

Construction Plan(model case)

Location

Soka-shi, Saitama, Japan

(TBC)

Cost

1.8 million USD

(depending on sales volume)

*Unit price per slot: 200-400 USD

Scale

- Number of container slots

-

3,546 slots

(depending on sales volume) - Effective surface area

-

495 sq.m.

(5337 sq. ft.)

*Slot: 1 unit of space to store 1 container

*From warehouse No.2 onward, projects to be realized in the 70-150 million USD scale

Schedule

Status

THE AUTONOMOUSRoadmap

“The phases leading up to full

automation of the logistics industry worldwide”

with Automated Picking Processes

and Suburban Areas Using Autonomous Drones